The Santoku is the traditional Japanese shape for a utility knife, comparable to the German chef's knife. The name 'three benefits' is derived from its versatility for cutting fish, meat and vegetables.

The Usuba blade shape is a traditional Japanese vegetable knife, and it is therefore used primarily for this purpose. Despite its axe-like shape it is not suitable for chopping bones.

The Yanagiba is a traditional Japanese slicing knife. Due to the slender, one-sided, hollow-ground and relatively long blade, the knife is particularly suitable for very thin cuts. The knife guarantees a skilful - and particularly clean, smooth cut. Such cuts are particularly important in the preparation of sushi. The length and shape of the blade allow for a long, pulling cutting movement.

The Deba is used in Japanese cuisine as a traditional axe. The sturdy, heavy knife has a strong, broad blade and a single cutting edge. The front part of the blade is used mainly for filleting fish. The rear part of the blade is stronger and is used, among other things, for cutting small chicken and fish bones.

refers to hardness tests according to Rockwell's C scale, employed for particularly hard materials. The Rockwell hardness value arises from the depth a testing object reaches whilst penetrating the test material (diamond, as the hardest material, serves as the value of reference with 100 HRC).

is characterised by its high carbon content, which ensures significant hardness. This gives it a very sharp cutting capability. Additional elements lend the steel greater elasticity and toughness, improving its corrosion and wear resistance. This makes A(US)10 knives less prone to rust and require less frequent resharpening.

is a corrosion-resistant stainless steel with a high chromium content and an average carbon content.

is a newly developed steel. Blades fashioned from this material are especially resistant to corrosion due to their high chromium content. This is a very pure type of stainless steel. Its greater carbon content ensures a better edge holding ability.

is a proven Japanese knife steel that offers a well-balanced combination of edge retention, corrosion resistance, and ease of re-sharpening. It is an excellent choice for anyone looking for a knife with versatile properties.

is a Japanese steel distinguished by its high flexibility and resilience. Thanks to its high chromium content, this blade steel is particularly resistant to both wear and corrosion.

does not refer to a particular wood species, but rather the general term for impregnated layered wood veneers bonded using high quality resins to ensure the handle's stability and guarantee lasting durability in the face of moisture and organic material.

Our collection of cutting boards and knife blocks is crafted exclusively from European wood species. We make sure that our raw materials are sourced from sustainable forestry. Besides first-class workmanship and a modern design, we consider this is an equally important aspect for the quality of your product. Kindly take note that wood is a ‘living’ material and that it will retain its natural properties, even after use.

Natural contents of wood, such as tannic acid and tannin, help prevent the formation of germs caused by food residues. Nevertheless, you should carefully clean and dry your cutting board or knife block after each use. Dirt can be removed with a damp cloth, followed by wiping dry. For more stubborn residues, vigorous scrubbing under warm running water with a little dish soap is effective. Afterwards, rinse thoroughly with clean water and dry completely. Never put cutting boards or knife blocks in the dishwasher or soak them in water. Instead, allow them to air dry thoroughly. Store wooden items in a way that allows air to circulate around them from all sides to prevent warping. Avoid drying wood products near radiators or ovens, as overly dry air can cause the wood fibers to crack.

Knives should only be stored in or on the knife block when they are completely clean and thoroughly dried. Oiled surfaces—such as cutting boards, chopping blocks, or knife blocks—should be regularly re-oiled. Our blade care set with Japanese camellia oil is ideal for this purpose. You can use it not only to care for your wooden cutting boards and knife blocks, but also for your knives (handle and blade).

You will enjoy using our products for many years to come if you observe these care instructions.

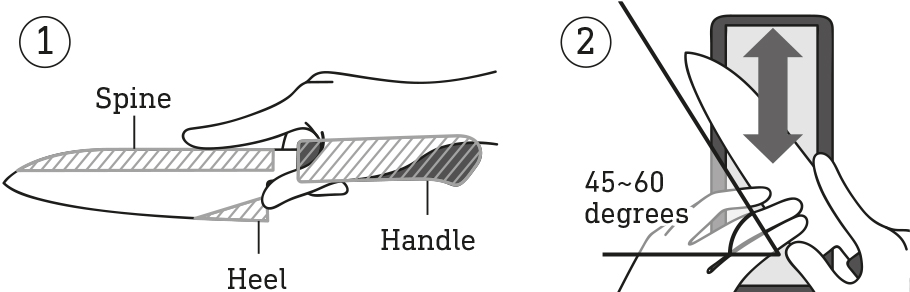

Soak the whetstone in water until no air bubbles appear, and keep the whetstone constantly wet while sharpening. Place the whetstone on a dedicated stand or on a wet cloth to prevent it from moving.

Hold the knife as shown in Figure 1, and sharpen the knife while maintaining a constant angle to the whetstone. As shown in Figure 2, position the knife so that the angle between the knife's cutting edge and the whetstone is 45-60 degrees.

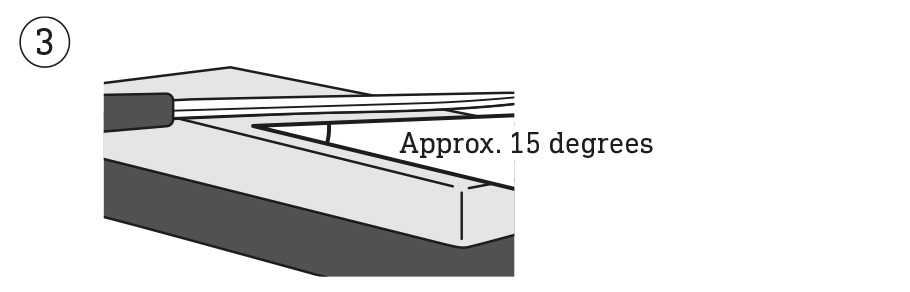

Double bevel knife: The angle between the whetstone and the knife should be about 15 degrees, as shown in Figure 3.

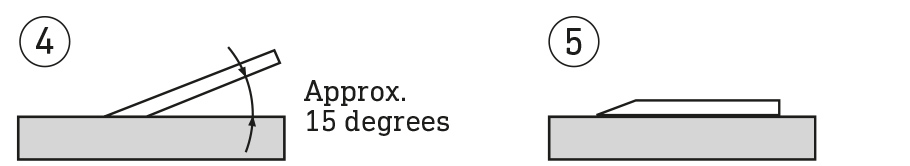

Single bevel knife: Place the knife on the whetstone as shown in Figure 4.

Sharpen the knife by moving it back and forth, using the full length of the whetstone, with just enough force to lightly carry the weight of your arm without exerting too much pressure. When burrs appear, sharpen the other side in the same manner until burrs appear. For single bevel knives, see Figure 5 for the knife angle. Once burrs have developed along both sides, spread newspaper on a flat surface and rub both sides of the blade to remove the burrs.

In order to continue sharpening accurately, use a flattening stone to flatten the surface of the whetstone.

Copyright © 2025. KAI EUROPE GmbH. All rights reserved.

Get notified about new products arrivals and early release info.

Sign up to our newsletter

Copyright © 2025. KAI Europe GmbH. Alle Rechte vorbehalten.